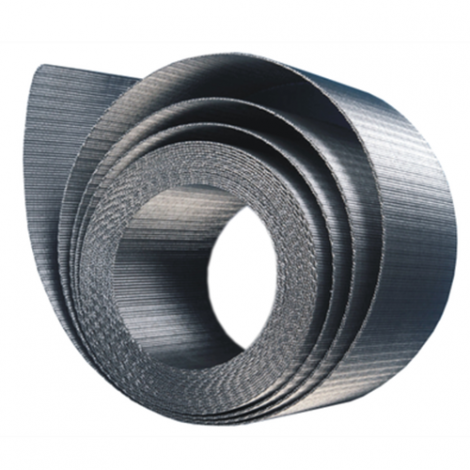

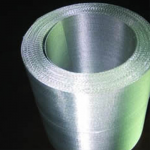

Reverse Dutch weave wire cloth is woven using two sizes of wire. Smaller wires are used in the warp direction and are woven with a larger shute wire. The smaller wires are woven tightly together, providing a tight mesh for filtering. The larger wire provides strength to the mesh. The primary uses of this wire cloth are filtration and separation of liquid and slurry products. Reverse Twill Dutch weave wire cloth combines Dutch and twill weaving to provide a fine mesh filtering cloth. The weaving process allows for the use of very fine wires, producing filtering mesh for gas and liquid applications. We also provide Herringbone and Broken Pattern Reverse Twill Dutch Weave Products. We also offer high tensile warp wire configurations that are commonly used in auto screen changers used in the plastic extrusion industry. We Wire offers custom wire configurations for wire cloth to meet the specific needs of its clients. For Dutch weaves micron-grade wire is most commonly used. In addition, DWT has the capability to manufacture: 1. High Tensile Warp wire for Auto-Screen changers used in the Plastic Extrusion Industry. 2. Rubbed Edges after slitting to help with tracking for Auto-Screen changers. 3. Plasma and laser cut parts to help prevent edges wire fraying. 4. 100% Inspection of Wire Cloth for critical applications such as sand screens and aerospace applications.